Tungsten Inert Gas (TIG) Welding

TIG Welding is also a slang term

commonly used. Tungsten inert gas welding (TIG welding) is a gas shielded

welding process and is one of the fusion welding processes. TIG welding’s

proper name is Gas Tungsten Arc Welding or “GTAW". This is the name the

American Welding Society and other welding organizations refer to this process

on their welding procedures. TIG welding also goes by the term HeliArc welding.

When TIG welding was introduced around

the 1940’s Helium gas was the primary shielding gas used in process. The term

Heliarc welding was the common phrase used back in the day Most old timers and

veteran welders refer to TIG welding as Heliarc welding.

Since the name includes the term

“Tungsten" and tungsten is what makes TIG welding possible, it is good to

know what tungsten is! Tungsten is a very hard, slightly radioactive, and

brittle metal. At 3380 degrees Celsius, tungsten has the highest melting point

of all pure metals in the periodic system. This means that the electrode does

not melt when it emits an arc that heats and liquefies the material. In TIG

welding the tungsten is made into a non-consumable electrode that is used to

create the arc for TIG welding.

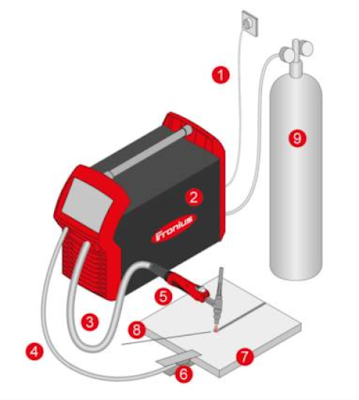

THIS IS HOW A TIG WELDING SYSTEM IS STRUCTURED:

(1) Mains connection

(2) Power source

(3) Hose pack

(4) Grounding cable

(5) Welding torch

(6) Ground terminal

(7) Workpiece

(8) Filler metal

(9) Shielding gas

TIG welding requires three things,

heat, shielding, and filler metal. The heat is produced by electricity passing

through the tungsten electrode by creating an arc to the metal. The shielding

comes from a compressed gas cylinder that flows to the weld area to protect it

from air. The filler metal is just a wire that is dipped by hand into the arc

and melted.

TIG Welding is a manual welding

process that requires the welder to use their both hands to weld. When TIG

Welding one hand is used for holding the TIG torch that produces the arc and

the other hand is to add the filler metal to the weld joint.

Shielding gas is selected according to

the material being welded. Argon - the most commonly-used shielding gas.

Helium and helium/argon mixtures

- adding helium to argon will raise the temperature of the arc. This promotes

higher welding speeds and deeper weld penetration.

In the TIG welding process the arc is

formed between a pointed tungsten electrode and the workpiece in an inert

atmosphere of argon or helium. TIG

welding must be operated with a drooping, constant current power source -

either DC or AC.

ADVANTAGES OF TIG WELDING

No formation of welding

spatter

Particularly high optical

quality of weld seams

All welding positions are

possible

Very high weld seam

quality

DISADVANTAGES OF TIG WELDING

Requires high degree of

skill

Low welding speeds

Rust must be removed

without fail when preparing the weld seam

Not suitable for thick

workpieces

2 comments:

For lash curling, an electric eyelash curler from a reliable and best eyelash curlers supplier can be a good option for a poyour curve

It is really awesome and informative post for welding. You can choose different brand from welding equipment store. You can also get quality safety equipment for welding at a comfortable rate.

Post a Comment